I haven’t been spending as much time on the Laser Project as I once did. Life, it turns out, often has other priorities. Still, I’ve furthered my understanding a bit.

Most of my work has been in tweaking a Q-switched laser that is intracavity frequency doubled. The shape of the beam profile looks like some variation of this:

Typical cavity design

This cavity design simulates very well. I’ve got a design like this to produce up to 4 watts of power for brief periods. But, no matter what tweaks I make to the design it always loses steam when I increase the power beyond a certain point.

The power loss seems to be caused mostly by mode hopping. Without second harmonic generation, mode hopping is undesirable and has a minor effect on overall power output. However, with frequency doubling, the change in beam shape makes a big difference in the beam intensity profile, and this causes large losses in harmonic conversion.

Hemispherical Cavity

One way to make a cavity less susceptible to mode hopping is to shorten it. A shorter cavity has a larger mode spacing and there is less opportunity for the beam to mode hop. So I’m trying a much simpler shorter cavity with only a single curved mirror:

Hemispherical resonator

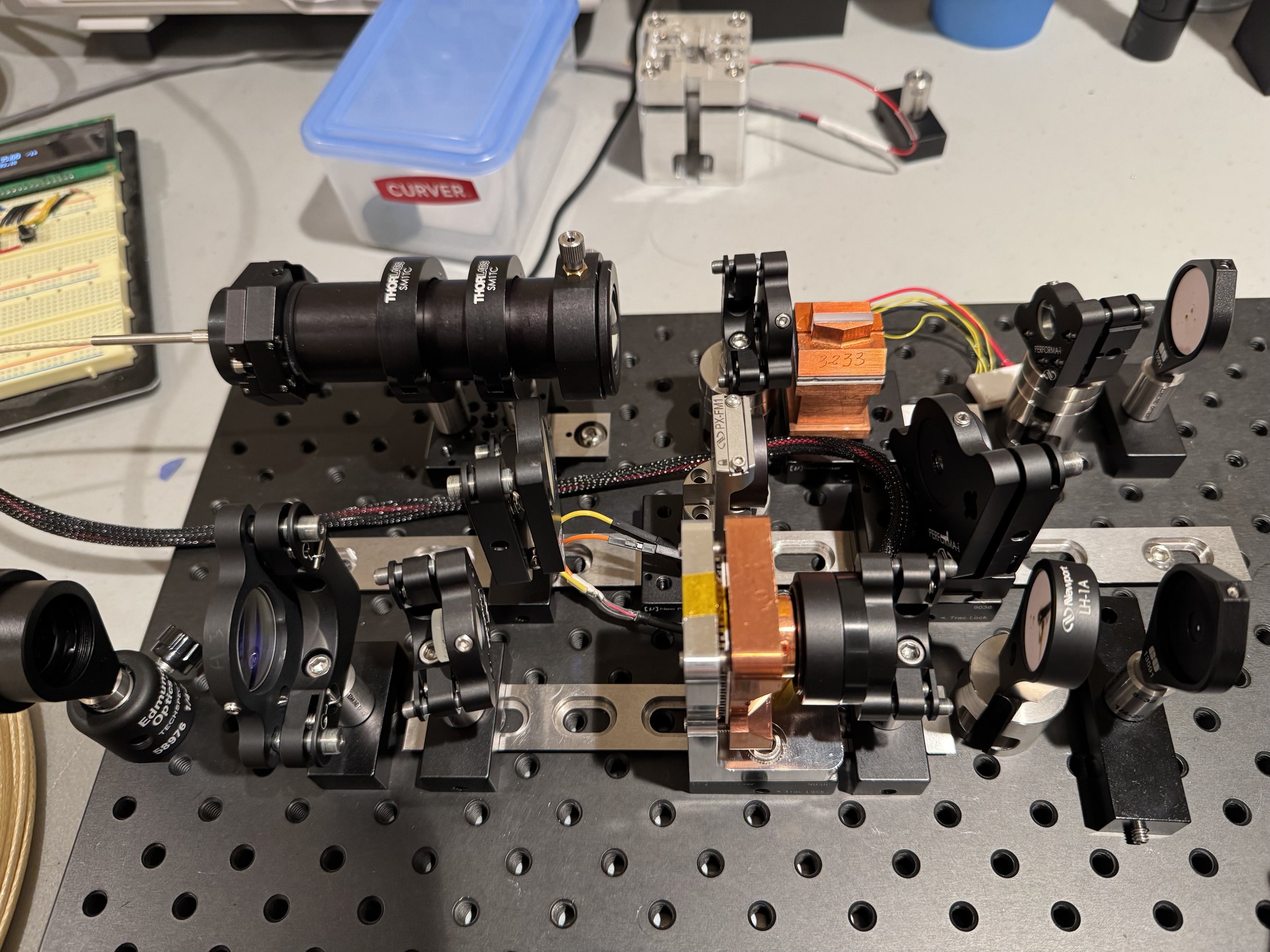

This is a hemispherical resonator design, and it is considerably shorter than the full confocal design I was using. I’ve built different variations of this design:

Continuous wave intracavity frequency doubled.

Q-switched, with external frequency doubling.

Q-switched intracavity doubled.

For the CW design, I was able to pump over a watt out of the cavity and it did remain stable. However, I can’t really get the beam radius small enough inside the KTP for every efficient conversion. I could only get about 4%. This results in a pretty terrible slope efficiency of about 19%.

The Q-switched design with external doubling is where I will go if I can’t get the green conversion where I want. The big disadvantage of this is to get any real power you’ve got to mix green and IR beams. You get the power, but the green isn’t nearly as bright. Also, there is a thing called “walk off” where the green beam coming out of the KTP is not in perfect alignment with the original beam. so over a distance you get two beams…one that is invisible. With an 80% Cr:YAG crystal I was able to get around 10-20% harmonic conversion.

The final design puts both the Cr:YAG and KTP in the cavity. These two need to be as close to the end mirror as possible. Also, this requires that you insert a harmonic separator between the Cr:YAG and KTP to keep the green beam from going back into the Cr:YAG. This isn’t ideal, because the intracavity beam needs to pass through the harmonic separator. Generally speaking, you don’t want to insert transmissive optics in the resonator because of the added loss going through the substrate. I could get a custom KTP crystal made with a HR 532 coating on one end, but this doesn’t actually work because the crystal often needs to be slightly angle tuned for maximum conversion. This design works pretty well, but still only yields about 20% efficiency.

Combining Confocal and Hemispherical Designs

I read a paper on mode locking using a saturable absorber. Normally you want to focus the mode area into the saturable absorber at a ratio of about 30:1 compared with the gain mode. In this paper they increased this to about 50:1 to saturate the absorber faster. I tried this with a pair of 100mm mirrors. The output to the KTP was about the same mode area as the gain mode, so I didn’t expect much performance. I was very surprised. This cavity performed very well. In fact, it performed better than my simulations by a large margin. I don’t know why this is. I saw some modulation of the pulse, but not enough for mode locking (which I don’t support in my simulation). Maybe even some modulation helps here. At any rate, the measured performance was pretty surprising:

Measured Performance

That made me wonder: what if I combined the tight focus of the confocal cavity with a curved harmonic separator to make the beam into the KTP tighter? The beam profile looks like this:

Combining confocal and hemispherical designs

The astigmatism at the gain is not great. This gets worse with each curved mirror that’s at an angle. However, this gives some very desirable characteristics:

The mode area compression about 40 for the Cr:YAG and 17 for the KTP.

The additional curved mirror helps with thermal lensing tolerance and the cavity is stable down to 13cm.

The design for this is below:

Performance of this design is pretty good. I’ve gotten almost five watts out of it on the bench (4.929). Bench performance is a little under what I predict, but the slope matches. Real world performance here often doesn’t match the simulation due to minor alignment problems, measurement errors in optic placement, etc. But I like this graph a lot:

Measured Power Output

The slope efficiency here is about 25%, which isn’t great. I can get this to 33% by improving the pump overlap, but this also makes thermal lensing worse due to the smaller pump size. The result is I get more power out with less power in, but the power tapers off at higher currents.

Nd:GdVO4

This crystal has much better thermal conductivity and should be able to accept more pump power before the cavity destabilizes. I decided to have two of these crystals manufactured. Unfortunately their performance hasn’t really panned out.

First, these crystals are very sensitive to external cooling. If you can’t wick the heat away, their performance takes a nosedive. I do have them temperature controlled in the real laser mount, but that’s not what I’m using on the workbench. I can cool them, but not regulate them. Even when cooled their power seems to fade pretty quickly after startup. I need to understand this better.

Second, these crystals don’t Q-switch very well. Their upper state lifetime is short (95µs) so they’re not going to be able to hold energy as well as Nd:YAG, but I assumed they would work as well as Nd:YVO4, which has an upper state lifetime of 98µs. This could be another cooling issue, as Q-switching is harder on the gain crystal.

I had two of these custom made. Now I have one. The one I was using fractured. I think this is some design defect in the crystal mount — I ruined a Nd:YVO4 crystal the same way using the same mount a year ago. It’s funny - I’ve avoided having another mount machined due to cost….and in the meantime fractured a $1000 crystal. The machining, by the way, was only $700. That last crystal remains unopened and will stay that way until I can build the final resonator with the right hardware.

Next Steps

This design shows promise, as does the Hemispherical cavity. I think the design I go with will be one of these. I have some tweaking of the cavity dimensions: I’d like to reduce the astigmatism and get the mode area to about 400µm. But I think I will need to re-tool the crystal mounts. Overall, more spend:

The gain mount would be better if I redesigned the base to mount direct to a surface mount beam rail. This will take less space, offer more flexibility, and help keep the pumps aligned down the crystal axis.

The KTP mount needs a bit of rework to its base so I can better butt the edge of the crystal to an end mirror. I also want to adjust some bevels on the side to allow for a shallower mirror angle. I would also like to have room for a teflon washer at the front that will hopefully better allow the angle of the KTP to be tuned. I have to keep the mount screws pretty loose now to adjust the angle.

I have pitted both the Cr:YAG and KTP crystals, and have some burn damage on the coating of one of the mirrors. These should be replaced. They work fine now for testing but I don’t want those damaged components in the final laser.

I want to move to an all rail design. It’s easier to align and get the right dimensions. I’m using rails for parts of the design but I need some longer rails to be able to do the entire design this way.

I will eventually need to buy a shearing interferometer to get the output properly collimated.