You know it’s a bad sign when my “hobby project” has quarterly updates….and has now been going for five years. But I learn a little each day. Let’s recap some of my recent knowledge.

Gain Crystal Types

Most of the gain crystals I’ve been using have come from eBay, and are often pulled from Coherent Verdi lasers. This is great, because the Verdi is pretty close to what I’m trying to make. These crystals have always been a bit of a mystery. Normally, when you align a cavity, you align all the mirrors with no other optics in place. Inserting the crystal might cause some slight alignment shifts, but it’s slight. Not so with the Verdi crystals. They are splitting the alignment laser beam into two beams — neither of which match the original alignment beam. I’ve worked around this by inserting the crystal and then adjusting a mirror three or four turns until I get a beam. This works…most of the time, but has it’s problems:

If you don’t have the pump laser mode pretty close to correct you may not get lasing. Getting a beam is a lot harder when there are two things that may need adjustment.

This re-alignment shifts the beam inside the laser cavity. For simple cavities there is enough “extra mirror” that this doesn’t matter much. But when you add things like KTP and a saturable absorber — both optics with pretty small apertures — often the beam gets clipped or misses the optic entirely.

For a while this was a complete mystery. Then I noticed that the Verdi crystals are not actually cut parallel — they’re cut so one of their end faces is angled just a little bit (like 1-2º).

I don’t have this issue with another crystal, and I’ve been using that crystal for most of my prototyping because it’s so much easier to align.

Last week I bought a couple new crystals off eBay and tried them out. They’re new in packaging and have parallel end faces. They also split my alignment beam. So the angled face of the Verdi crystals is not causing this beam deviation after all!

Perplexity solved it. I’ve been throwing ideas at Perplexity as a fast way to rip through research papers. I learn a lot, but man, you are a fool if you trust generative AI without verifying it. Equations it gives are often wrong, but it does lead me in the right direction so it has a lot of value. In this case, it outlined the difference between A-cut and C-cut laser gain crystals. A-cut crystals will refract e-polarized rays at one angle and o-polarized rays at another. This is why I am getting two spots, and the other crystal I have that doesn’t exhibit this is actually C-cut (one of the problems in buying things off eBay is you don’t always know exactly what you’re getting).

Earlier I had considered polarization of my alignment laser. I tried using a 1/2 wave plate to rotate it, and I even tried rotating the laser. The 1/2 wave plate made no difference, and rotating the laser would prevent the laser crystal from showing any spots.

I am an idiot.

My alignment laser is polarized….but it is rotated in its mount so it’s contributing some O and some E output. This will prevent the 1/2 wave plate from doing what I expected. And rotating the actual laser? Well the beam is not perfectly centered so when I rotated it the beam was no longer falling on the crystal. Doh! (In my defense this is all invisible and I need to use a camera to see it, so it’s easy to miss things).

Today I rotated the alignment laser, re-aligning with the crystal after each turn, and managed to only get a single spot out of the crystal. And I was abler to align with the crystal in place and the cavity started lasing on the first try. That’s a five year conundrum solved.

Focusing into KTP

You need a really intense inside the KTP for it to convert infrared to green light. The best way to do this is to focus the beam into the KTP. But, KTP has this thing called “critical phase matching”. It’s “critical” because if it’s not perfectly matched the conversion efficiency goes down fast. When you focus a laser beam, that causes the beam to diverge and that can cause a phase mismatch. So I had been staying away tight focusing. Well, I found that as long as the Rayleigh Length of the beam is not shorter than the crystal the phase mismatch is negligible. So, with this handy formula and a given crystal length you can calculate the minimum safe spot size in the crystal:

$$w_{min} = \sqrt{\frac{L_{shg} \lambda}{\pi n}}$$

For my 10mm crystals this is a minimum waist of about 60µm.

New Cavity Designs

I’m trying out a new cavity design. My designs tend to have three “rows”: a gain row, a Q-switch row, and a KTP row. I know how to align a design like this and the rows allow some isolation, so you can extract the 532nm light without leaking it back into the cavity. I’ve always done Gain, Q-Switch, KTP. For giggles I switched to Q-Switch, Gain, KTP. Why? The biggest issue I have to deal with is thermal lensing of the gain. By putting it in the middle there’s less cavity length the thermal lens can act on. And boy does it make a difference. This cavity is stable all the way down to under 10cm of lensing.

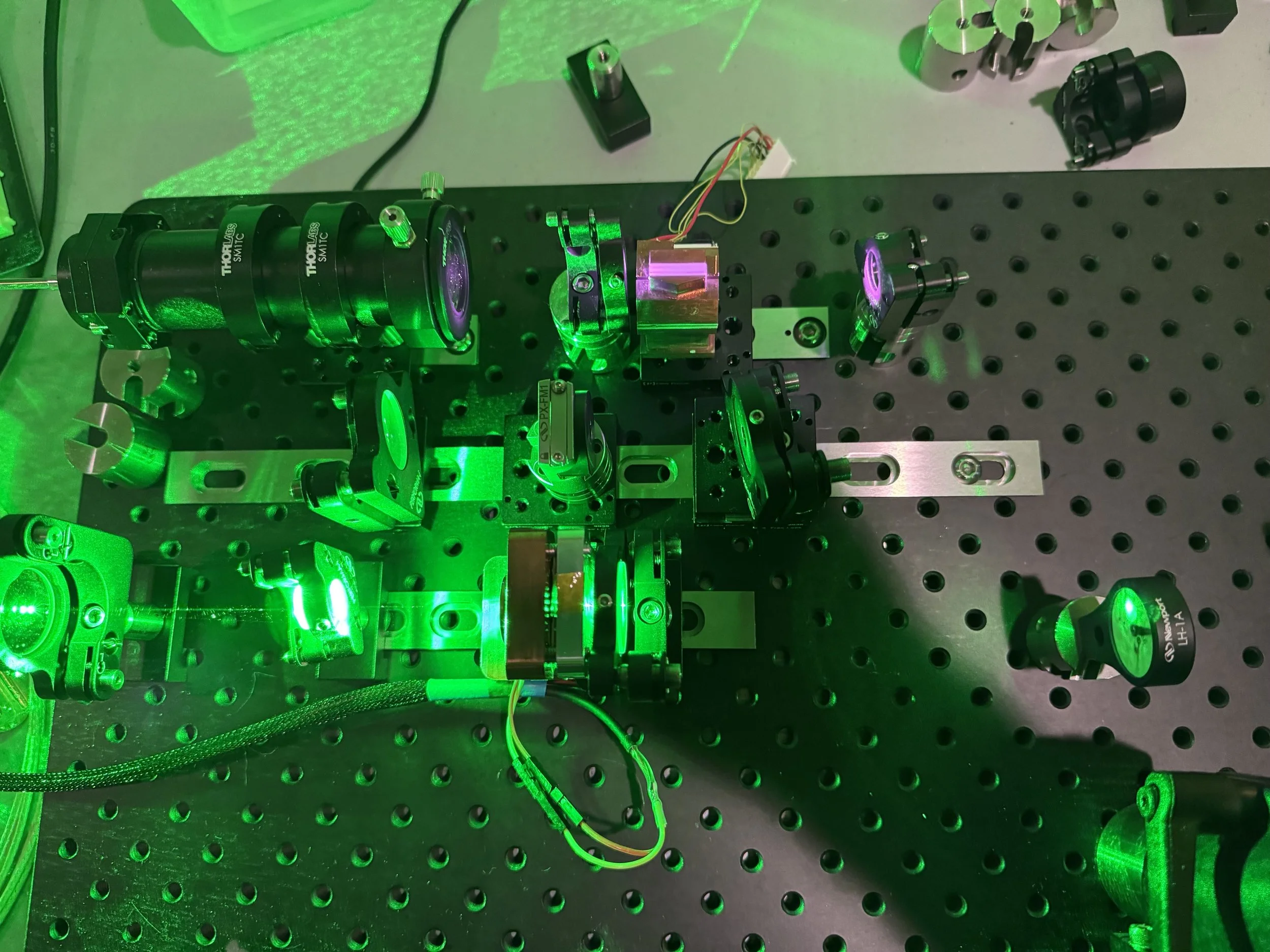

Below is a beam waist diagram for the new design, along with a photo of the built version. The laser works, but I have not yet replaced the output coupler with a HR1064/532 so it produces only green light. I’ve had some unfortunate accidents lately when I do this I and up blowing a hole in a mirror. Which sucks, because the mirror I keep doing this to is the only one I have and I haven’t found another (and custom making it is about $4000, so I’d like to not do that). Luckily I can just reposition it to avoid the damaged areas.

But I intend to take a lot of measurements from this new design. Hopefully it’s a winner.