I’m going to use two Coherent FAP800 40 watt 808nm fiber coupled laser modules as pump sources for my laser. These can be found on eBay used for significantly less than their new cost (which is around $3000 I believe. It’s one of those “call to ask” things). Laser diodes need carefully regulated constant current power supplies: if you just hook them up to a battery or standard constant current supply they will burn up. These modules take up to 53 amps each, and I couldn’t find a ready-made supply that could do this that wasn’t a ton of money (and none of them could be run off batteries).

So I designed my own. You know what also needs a constant current power supply that can deliver a lot of current? LED headlamps for cars. I found a great chip that is made for this: the MAX20096. This chip has dual outputs and can be controlled by by a microcontroller through a SPI interface. Lots of math, design work and PC board fabrication and I got this:

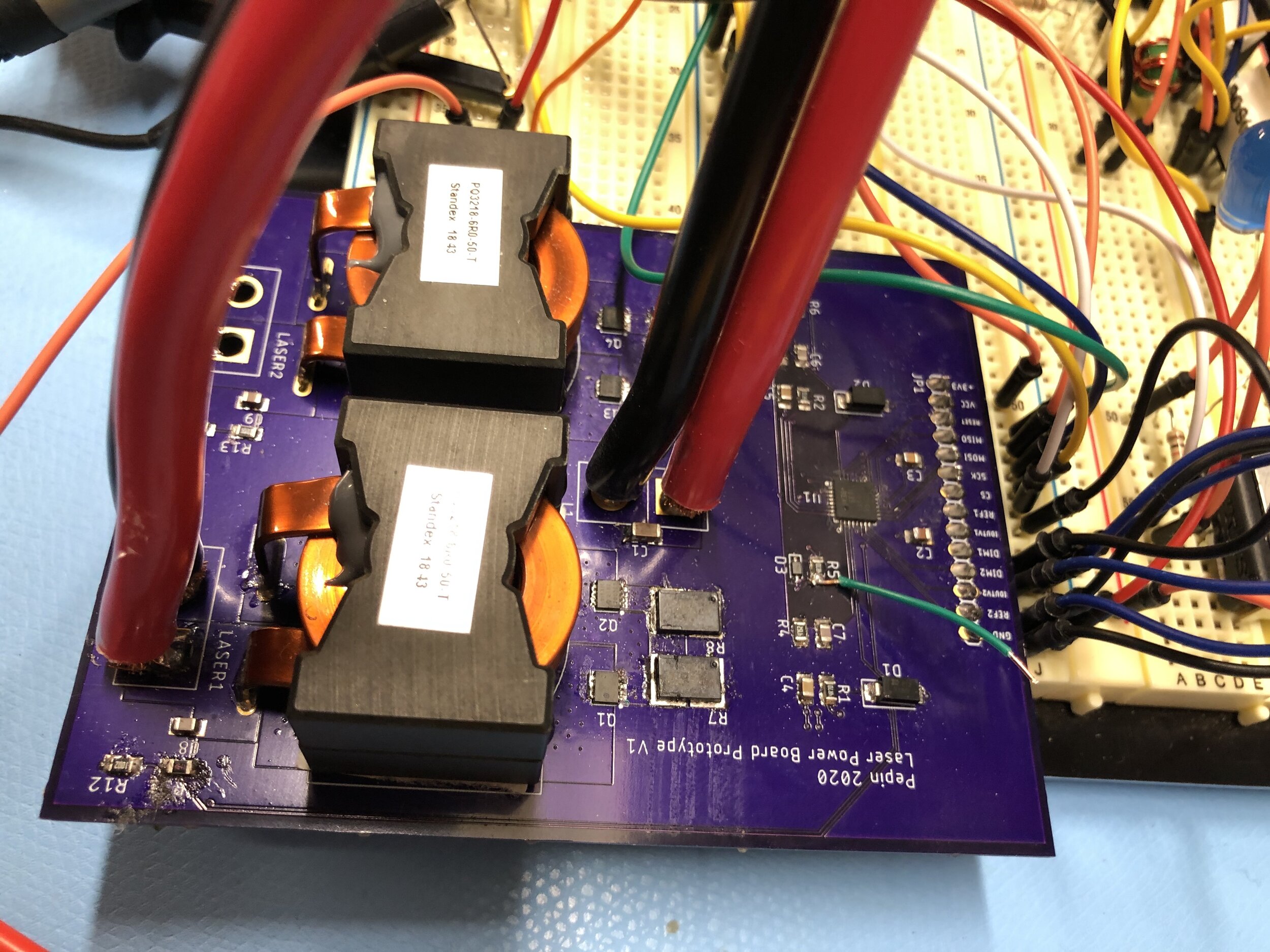

My first attempt at a constant current switch mode power supply.

…and it didn’t work at all. At light loads it works. At higher currents it produces so much electromagnetic interference my microcontroller can’t even talk to it. The problem turned out to be my board design. I designed for good thermal management of the parts that need to dissipate heat but thought nothing of the high currents racing around the board at 500kHz. Basically, this board is an unlicensed radio transmitter.

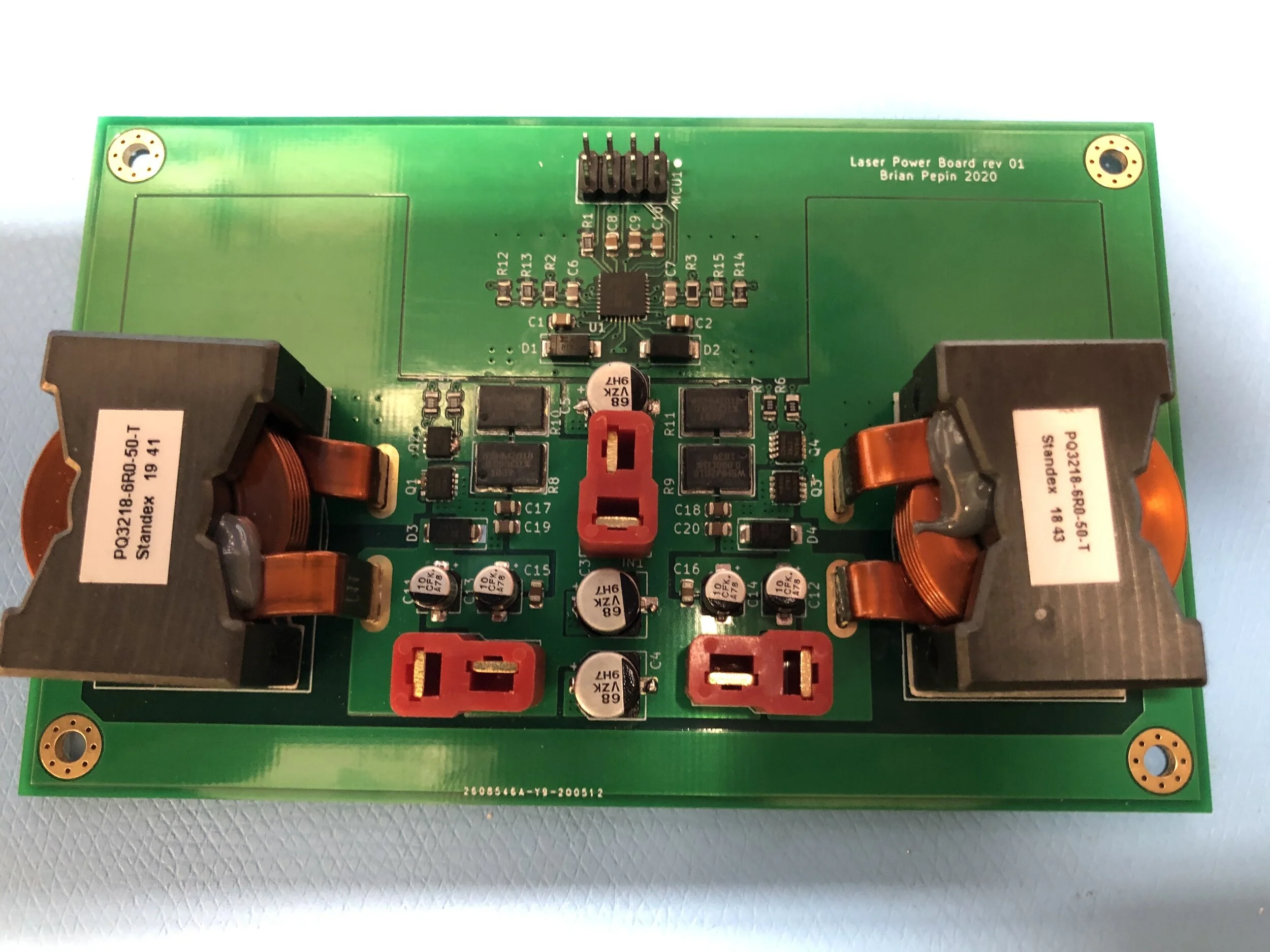

Board version two looks like this:

Revision two. Success!

This board uses most of the same parts as the first board (I improved the filtering capacitors), but is a four layer board and I paid close attention to current loops. Notice how close the parts are and how there is a distinct section for the power electronics separate from the control IC. This was a success! Ripple looks good and it has no problem running each channel up to 50 amps. Reporting through to the microcontroller shows pretty accurate current monitoring.

So will it power the laser modules?

Raw laser module output. Current set to 48 amps

Yup. Next up: hooking up the fiber optic cables.